The manufacturing industry is a vast industry. There are several components created in a manufacturing firm. Since it is an asset-intensive industry, a manual process can be extremely dangerous for businesses, which is why asset management software is essential for the manufacturing industry. In this blog, we will learn why the manufacturing industry needs Asset Management Software! So, without wasting any time let us begin!

What is Asset Management Software?

Asset management software automates the process of asset tracking. Asset tracking is important for all industries including the manufacturing industry for checking the status of asset health and its performance. Apart from that asset tracking enables you to provide accurate location of assets. Most importantly it helps in managing and increasing asset life cycle.

For better asset lifecycle management this asset management software can be a game changer. Furthermore, this software assists in asset maintenance and avoids sudden asset failure. Asset failure is one of the main issues of the manufacturing industry because it not only impacts on the bottom line but also the work process slows down and production work halts as well. -

Why Manufacturing Industry requires asset management software?

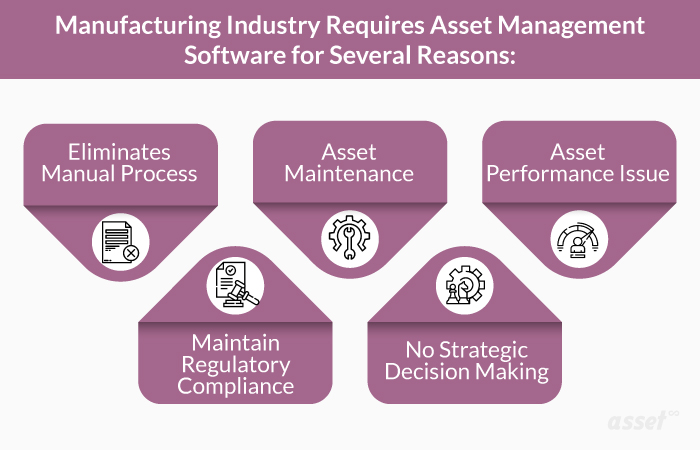

Manufacturing Industry requires asset management software for several reasons:

Eliminates manual process

Many manufacturing-based organizations are not equipped with any automated application. As a result, they suffer from several issues such as data inaccuracy and no proper tracking of assets. For data tracking, an organization uses spreadsheets, but spreadsheets must not be used for keeping track of assets. The spreadsheet is not accurate because lots of employees access it, and errors can occur due to manual data entry. This can create problems in the whole procedure.

However, our asset management software eliminates manual processes, and spreadsheets are not utilized as well. It automates the process, and every asset is tagged which helps in keeping track of assets.

Asset maintenance

Manufacturing organizations have lots of assets and they are complex in nature, that’s why they must be inspected, and maintenance must be scheduled at regular intervals. However, that does not happen so unexpected equipment breakdowns are frequent.

With asset management software you can schedule asset maintenance for every asset individually. This software also provides alerts for upcoming maintenance so that the maintenance team can prepare accordingly. After the implementation of this software, you will notice that the unexpected equipment breakdown has decreased, and overall maintenance expenses decreased as well.

Asset performance issue

When assets are not properly maintained or not provided maintenance on time then as it starts performance asset performance starts decreasing and the machine's productive life ends before its actual time, therefore, it is important to keep track of performance.

For that purpose, you can raise a ticket with this software. You can raise the ticket and track the status of every ticket. Moreover, you can prioritize tickets and complaints. Whenever any ticket is raised the help desk management is notified and the manager assigns the ticket to the available technician. You can give detailed information about issues in assets and pictures, or videos can be given for better understanding. Furthermore, it gives real-time reports and analytics.

Maintain regulatory compliance

Maintaining compliance is important for all organizations according to their sectors. For example, it is important that you maintain a complete asset list and that all the papers and documents related to every asset are there. If during an audit it is found that the organization's assets do not match the asset numbers list, they provided, then they might end up paying huge penalties. Similarly, for manufacturing organizations, it is important that all safety measures are followed for employees. If an organization does not follow compliance, then the organization might end up paying huge penalties.

Asset Infinity’s asset management software provides an asset register in which a complete asset list is mentioned including all the information related to every asset. This asset register plays a crucial role in asset audit, asset maintenance, and maintaining compliance. This software has also the feature of movement history that lets you know the exact location of the asset.

No strategic decision-making

In business, every step is taken very carefully, that is where you will require data. Since the data is managed manually chances are that data is inaccurate & insufficient and there is no proper way to organize this data and utilize it to make informed decisions.

With this asset management software, you can ensure data accuracy and data will be sufficient (all required data will be there). Furthermore, you will get detailed organized reports that will be helpful to organizations in order to make strategic business decisions. You can get customized reports as per your requirement. These reports are helpful in setting future goals and setting future objectives.

Conclusion

For manufacturing-based organizations, it is important for them to utilize automated management software. If they go for the manual method then productivity will not increase, and the organization will have to face issues constantly. This provides a systematic approach to managing assets efficiently. It enables you to make the most out of assets and plays a crucial role in boosting ROI (return on investment). This system centralizes asset information and helps organizations in planning and schedule activities accordingly.

Overall, Asset Infinity provides an application that manages assets, and items for an organization & keep track of assets to avoid theft, and misplacement. It keeps track of asset life in all stages and alerts you when its productive life is over. Therefore, the system not only is helpful to the maintenance team, but it will also help the whole organization in delivering productive work.

Frequently Asked Questions (FAQs)

Does this software come with cloud technology?

Yes, this software comes with cloud technology. Cloud technology enables you to access data from anywhere and gives you flexibility.

What are the manufacturing assets?

Machinery, production lines, Moulds, die, raw material ad inventory, etc. Are the assets for manufacturing-based organizations.

.png)

.png)

.png)